Automatics for garage doors, windows, gates are durable, reliable devices with a long working life. However, even with high quality equipment malfunctions occur, so that there is a need for its repair.

Signs and causes of malfunction

Repair of the garage opener is required when

-there are extraneous noises in the drive during its operation;

-the sashes or canvas of the structures move jerkily, stick;

-there is no reaction to pressing a button on the remote control or stationary switch;

-the door leaf, roller shutter, or doors do not stop at the right moment.

One of the reasons for such situations is incorrect adjustment of automation of swing gates or other types of structures. Specialists should install and adjust equipment. We not only sell automation for windows, doors, and gates but also perform its installation. Our installers will do everything qualitatively and quickly, with a guarantee for the work done.

Other most common causes of malfunction of garage opener:

-sharp voltage spikes in the power grid

-depressurization of the housing of the control unit;

-drying or freezing of grease;

-excessive loads;

-wear and tear of parts and assemblies.

Knowing the symptoms and causes of their occurrence, you can quickly eliminate all malfunctions and return functionality to the automation. The peculiarity of the repair of the drive is that the equipment consists of mechanical and electronic parts. In this case, one without the other does not work. Most often, the electronic component fails, and mechanics fails quite rarely.

Troubleshooting garage opener at voltage fluctuations in the network

The most common cause of failure of the electric actuator is unstable voltage in the supply network. Both its increase and decrease are dangerous. At low voltage, the actuator works as if once in a while, which is not normal and can lead to its failure.

If the automation does not respond to commands from the remote control, as well as the button panel, then most likely the problem is in the electronic board. It should be inspected for blown fuses, burned charred parts. If a strong burnout is detected, the board will have to be discarded and a new one purchased. Sometimes it is enough to replace the fuse or simply reconfigure the automation.

Logic board

Most often during voltage surges, the varistor burns out. It is carefully unsoldered, and then install a new one with similar parameters.

If visually burned parts are not visible, then it is necessary to use a tester-multimeter to check the primary winding of the transformer. If it is not electrically energized, then it is damaged. In this case, the transformer should be replaced.

Sometimes, you may encounter a failure of the reed switch reed switch. You can recognize that the problem is in the reed switch by the light indicators on the OL and CL limit switches. If no magnets are connected to the reed switches above the gear wheel (the gate is in the middle position) and both indicators are lit, the part is in good working order. Otherwise, the burned reed switch should be replaced.

Another cause of malfunction is poor wiring connection. It is eliminated by searching for areas with a broken or broken wire and restoring its integrity.

Restoring the tightness of the control unit

If the housing is cracked or loose to the base, then dust, water, various insects and debris get into the control unit. They have a detrimental effect on the board and can put it out of service or throw off the settings.

In order not to aggravate the situation, it is necessary to replace the broken case with a new one in time. Otherwise, it will be necessary to replace the individual elements of the control unit or the entire board.

Does the barrier not work? It is easier to repair than to buy a new one!

Modern automatic barriers, even in the minimum configuration, cost several tens of thousands of rubles. Therefore, if a private person or organization decides to purchase such a design, they expect that the system will serve as long as possible.

Read more

Replacing the factory lubricant

Dried or frozen due to frost factory grease can cause the appearance of uncharacteristic noises in the drive when opening and closing swing, sectional, or sliding gates. In addition, they begin to respond incorrectly to commands from the remote control and move jerkily. If you do not pay attention to failures in the work and do not eliminate their cause, the situation may worsen – the gearbox will break, and the cost of repair of automatic gates will increase. To avoid this, the first malfunctions should replace the lubricant and then reconfigure the electric drive.

Replacing worn parts

Over time, individual mechanical parts of the actuators fall into disrepair. Such elements include, for example, gears, bearings, and opener shaft assembly. Spare parts can be ordered from our catalog on the site. There are original parts of the DoorHan brand at the manufacturer’s prices.

Incorrect choice of the electric drive can also lead to its breakdown. For example, if you install a household model on an industrial gate, it will not cope with a heavy canvas. The drive will be subjected to excessive load, as a result it will fail very quickly.

A garage opener for industrial sectional gates should be selected, taking into account the size and weight of the leaf. In this case, the power should have a reserve of 30% in case of the structure being weighed due to snow buildup or icing.

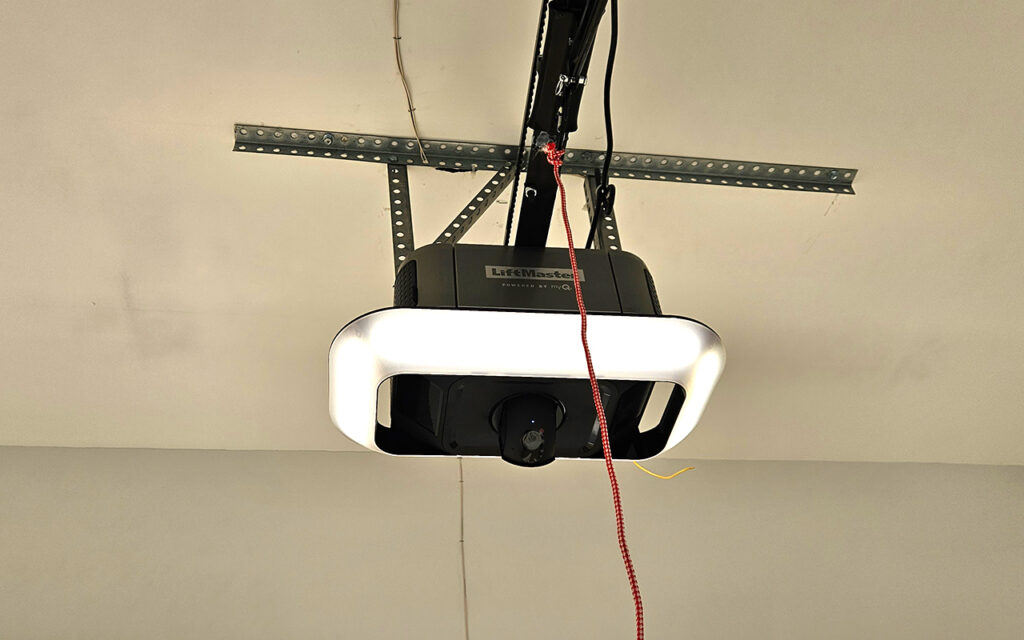

Liftmaster drives for industrial sectional doors.

Prevention of automation breakdowns

To prevent breakdowns, as well as to increase the service life of the gate, automation will help to comply with some rules:

Protect the power grid from voltage fluctuations by installing a voltage stabilizer. Its power should be twice the power of the drive. Models with a stabilization power of 1.5-2.0 kW are suitable.

Regular inspection of the actuator and other elements of automatic control. Worn parts should be replaced, and loosened parts should be tightened.

Prevent foreign objects from entering the gate’s working space and automation.

Maintenance of the gate 1-2 times a year. It includes, for example, lubrication and tension adjustment of the chain of the ceiling electric drive of garage sectional doors. Such work should be carried out by trained specialists.

Keeping the drive and garage door clean and outdoors. It is important to wipe the screens of the receiver and transmitter of photocells, especially after snowfall, to monitor the integrity of electromagnetic limit switches (if any), especially if there are pets.

With systematic maintenance and care of automatic gates, they will work properly for many years. But if a breakdown does occur, you should not try to fix it yourself. In the absence of proper experience, it may lead to more expensive repairs. We recommend to contact the nearest service center “DorHan”. This will help to reduce the time for repair and avoid mistakes due to lack of experience.

Specialists will conduct an in-depth diagnosis of the failed electric actuator, and then promptly eliminate the cause of failure. Defective parts are always replaced with new original spare parts. A warranty is provided for all components and works performed. High-quality service will improve the operation of garage opener and significantly extend their service life.

Comments are closed